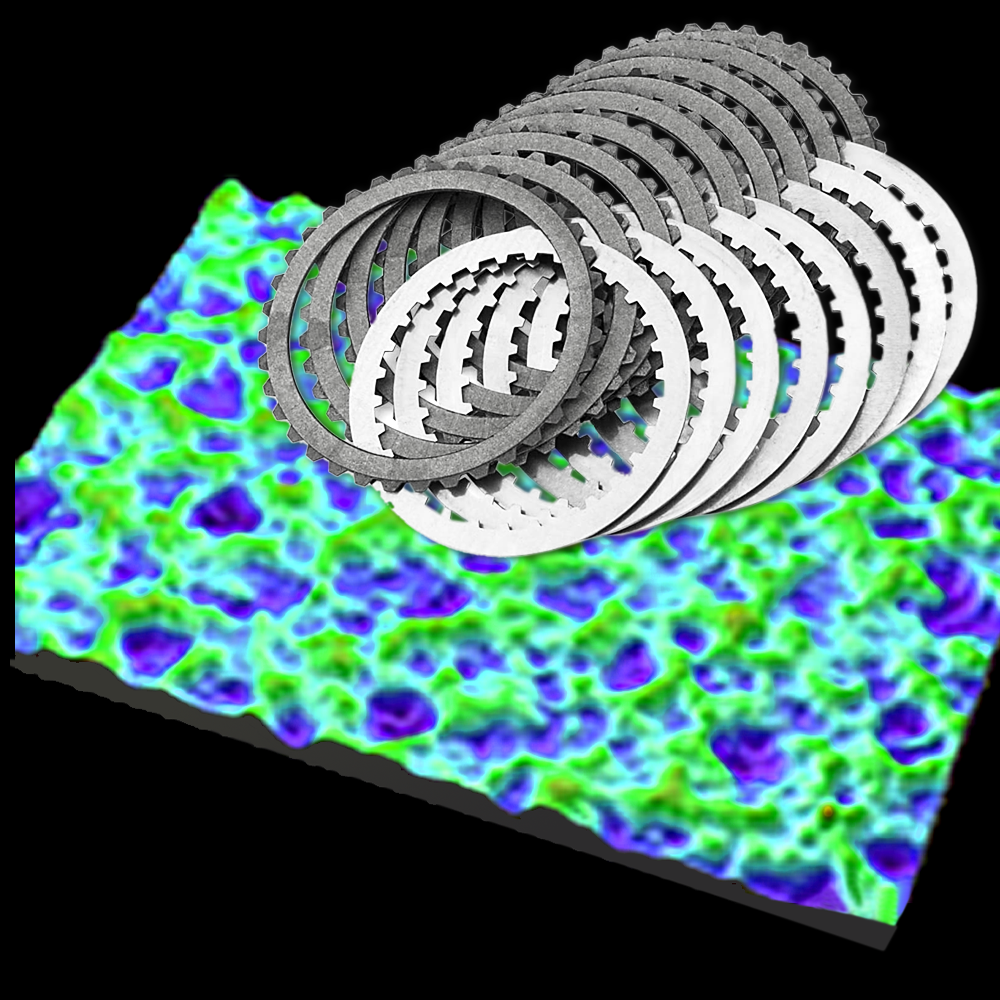

Transmission clutch mechanisms and other complex systems require tight control of friction characteristics.

Surface texture parameters such as Peak Heights, Valley Depths, Spacings and other bearing area related parameters (Spk, Sk, Svk) can be specified to control production processes and optimize friction characteristics.

Michigan Metrology has been on the forefront of relating surface roughness to friction and tribology for almost three decades. When your application requires control of finish and friction, call Michigan Metrology to help with measurement, specification and production control.

Issues we address: